1.0 ANALYTIC TECHNOLOGY

- State-of-the-art advanced computer technology enables EK to reduce the overall weight by 3% without compromising tensile strength, which in turn extends the life of the chain.

Industry leading machining process of all metal surfaces helps create an unmatched and optimal seal of all EK O-Ring and X-Ring chains.

- Additionally, mud and dirt build-up is significantly reduced via this technology.

2.0 HEAT TREATMENT

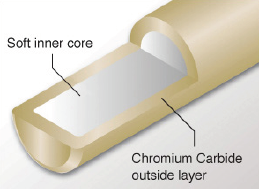

- All EK off-road race chains utilize EK’s exclusive CRH pin treatment process, which provides an extremely hard outside coating and softer inside to increase strength and reduce wear.

- Superior impact and shock absorption, and reduced oxidation is also a result of EK’s Chromium Carbide pin surface coating.

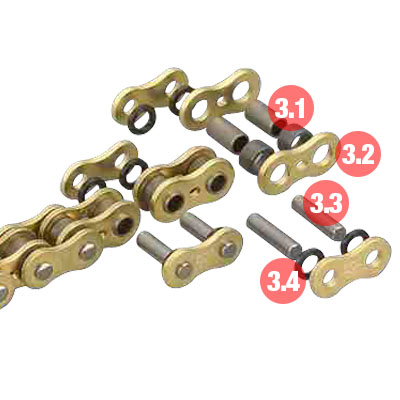

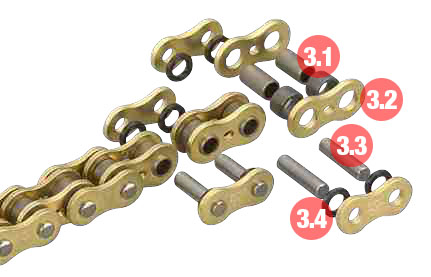

3.0 MATERIAL ANALYSIS

3.1 BUSHING & ROLLER: EK’s research and development has indicated that one of the initial points of failure is the chain roller – therefore EK features the thickest chain roller in the industry to prolong chain life.

3.2 INNER PLATE: The inner plates have been designed to minimise weight without sacrificing strength which results in increased power and a longer chain life.

3.3 PIN: The exclusive CRH treatment provides an extremely hard outside coating and softer inside to increase strength and reduce wear.

3.4 SEAL RING: EK’s advanced X-Ring technology gives EK unprecedented life on all sealed chains.